5 Practical Ways Gemini Enterprise Solves Manufacturing’s Labor and Efficiency Crises

For manufacturers across the US and Canada, the era of "business as usual" has officially ended. The sector is currently navigating a perfect storm of pressures: a persistent skilled labor shortage (the "silver tsunami"), volatile global supply chains, aggressive sustainability mandates, and the constant squeeze on operating margins. While Industry 4.0 promised a revolution, many organizations remain stuck in "Pilot Purgatory" possessing vast amounts of data from sensors and ERPs, yet lacking the agility to turn that data into real-time decisions.

Traditional tools—rigid legacy cores, fragmented spreadsheets, and siloed SCADA systems—are no longer sufficient to maintain a competitive edge. Leaders do not need more dashboards; they need intelligent synthesis. They need systems that can reason across complex datasets, predict disruptions before they halt the line, and empower a new generation of workers with the institutional knowledge of their predecessors.

This is where Gemini Enterprise on Google Cloud shifts the paradigm. It is not merely a chatbot or a productivity add-on; it is a sophisticated, multimodal AI platform capable of ingesting data, images, and video to act as a secure, intelligent agent. At Evonence, we help manufacturers move beyond experimental AI, deploying trusted, grounded Gemini solutions that drive OEE (Overall Equipment Effectiveness), reduce risk, and secure the future of operations.

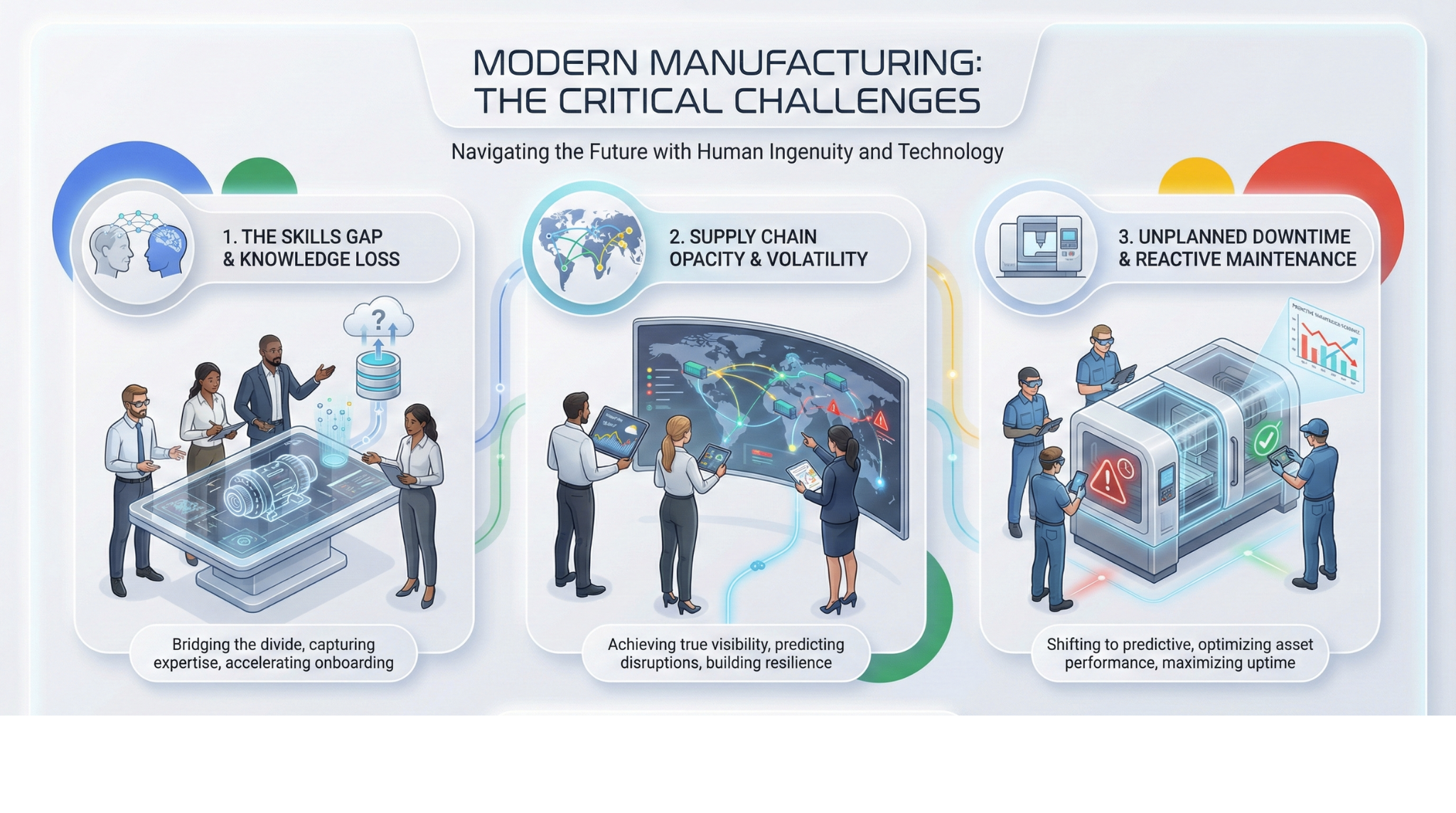

The Critical Challenges Facing Modern Manufacturing

Before discussing solutions, we must address the specific friction points slowing down North American manufacturers today.

1. The Widening Skills Gap & Knowledge Loss

As senior engineers and floor managers retire, they take decades of "tribal knowledge" with them. New hires face a steep learning curve, often struggling to troubleshoot complex machinery because the answers are buried in 500-page PDF manuals or legacy databases that are difficult to query.

2. Supply Chain Opacity & Volatility

Despite investments in ERPs, true end-to-end visibility remains elusive. Disparate data sources—supplier emails, logistics portals, and internal inventory logs—make it nearly impossible to predict shortages accurately. Manufacturers are often reacting to disruptions days after the warning signs first appeared in the data.

3. Unplanned Downtime & Reactive Maintenance

The cost of one hour of downtime in an automotive or CPG plant can range from tens to hundreds of thousands of dollars. Most maintenance is still schedule-based (preventive) or failure-based (reactive), rather than truly predictive. The data exists to predict failure, but it is locked in noise that human analysts cannot process fast enough.

4. Quality Assurance (QA) Bottlenecks

Manual visual inspection is prone to human error and fatigue. While traditional computer vision exists, it is often brittle and hard to retrain for new products. This creates bottlenecks where production speed outpaces the ability to verify quality, leading to rework and waste.

What is Gemini Enterprise?

For the manufacturing executive, Gemini Enterprise is best understood not as a "search engine," but as a reasoning engine that sits securely within your Google Cloud environment.

Multimodal Capability: Unlike older AI that only understood text, Gemini can process and reason across text, code, images, and video simultaneously. It can "look" at a picture of a rusted valve and "read" the maintenance log associated with it.

Enterprise-Grade Security: This is not a public consumer tool. Your data never leaves your environment to train Google’s base models. It adheres to the same strict security standards (SOC 2, ISO 27001) that govern your existing Google Cloud infrastructure.

Grounded Agents: Gemini Enterprise allows us to build "agents" software entities that can use tools. They don't just answer questions; they can query BigQuery, look up a status in SAP, or draft a root-cause analysis report based on specific incident data.

Integration Ecosystem: It operates seamlessly with the tools you already use or are migrating to: Google Workspace, Vertex AI, BigQuery, and Looker.

High-Impact Use Cases for Manufacturing

At Evonence, we focus on deploying Gemini Enterprise where it impacts the P&L. Here are five concrete ways we are seeing this technology transform the factory floor and the back office.

1. The "Shop Floor Copilot" (Maintenance & Repair)

The Problem: A critical machine fails. The junior technician doesn't know the fix and the expert is off-shift. The machine stays down while they search through physical manuals.

How Gemini Solves It: We build a multimodal agent grounded in the manufacturer’s technical documentation, historical repair logs, and SOPs.

Workflow: The technician takes a photo of the error code or the damaged part using a ruggedized tablet. Gemini analyzes the image, cross-references it with the technical manual, and provides step-by-step repair instructions in the technician's native language.

Outcome: Drastic reduction in Mean Time To Repair (MTTR). Junior staff perform at the level of senior staff.

2. Intelligent Supply Chain Control Tower

The Problem: Supply chain managers spend 40% of their week scraping data from emails, PDFs, and ERP screens to answer simple questions like, "Do we have enough raw material for the Q3 surge?"

How Gemini Solves It: An agent connected to BigQuery (which aggregates ERP and supplier data) and unstructured data sources (vendor emails/contracts).

Workflow: A VP of Ops asks, "Show me the impact of the port strike on our resin inventory." Gemini queries the live data, factors in the logistics delay news, and generates a risk assessment with suggested alternative suppliers.

Outcome: Proactive risk mitigation. Shift from "fighting fires" to strategic planning.

3. Automated Root Cause Analysis (RCA)

The Problem: After a quality incident or safety near-miss, engineers spend days compiling data from historians, shift logs, and emails to write an RCA report.

How Gemini Solves It: An agent that ingests time-series data from the historian and text logs from shift reports.

Workflow: The engineer uploads the incident timestamp. Gemini correlates the sensor anomalies (e.g., temperature spike at 14:00) with the shift notes ("Operator adjusted valve B"), identifies the likely correlation, and drafts the RCA report for human review.

Outcome: faster incident resolution; creates a feedback loop that prevents recurrence.

4. Visual Quality Inspection Assistant

The Problem: Retooling a production line for a new product requires retraining expensive computer vision cameras, which can take weeks of coding.

How Gemini Solves It: Gemini’s multimodal capabilities allow for "zero-shot" or "few-shot" learning.

Workflow: A QA manager shows the system five images of a "good" part and five images of a "defective" part. Gemini can immediately begin flagging anomalies on the video feed without complex model retraining.

Outcome: Faster New Product Introduction (NPI) cycles; reduced scrap rates.

5. Generative Design & BOM Optimization

The Problem: Sourcing components for a Bill of Materials (BOM) is complex. Engineers often default to expensive parts they know, rather than optimizing for cost or carbon footprint.

How Gemini Solves It: An agent with access to supplier catalogs and sustainability databases.

Workflow: An engineer uploads a CAD spec. Gemini suggests a list of alternative materials that meet the tensile strength requirements but offer lower cost or better carbon footprint ratings, citing the specific datasheets.

Outcome: Improved margins and progress toward ESG goals.

Architecture & Trust – How It Works on Google Cloud

For the CIO and CISO, the "how" is just as important as the "what." Deploying Gemini Enterprise in a manufacturing environment requires a robust, secure architecture.

Connecting IT and OT Data

The power of Gemini lies in grounding. We do not want the AI to hallucinate; we want it to answer based on your reality.

Ingest: We use Google Cloud’s data ingestion tools to pull data from your ERP (SAP, Oracle), MES, and Historians into BigQuery.

Unify: BigQuery acts as the single source of truth, handling structured data (sensor readings) and unstructured data (PDF manuals, logs).

Ground: Using Vertex AI, we configure Gemini to "look" only at your trusted data in BigQuery and Cloud Storage when answering queries.

Security & Sovereignty

Your Data is Yours: When you prompt Gemini Enterprise, your data is not used to improve Google’s foundational models.

VPC Service Controls: We deploy these solutions within a Virtual Private Cloud (VPC), ensuring that sensitive intellectual property (like schematics or formulas) never traverses the public internet.

IAM & Access Governance: We apply granular Identity and Access Management. A floor operator agent will have different data permissions than a procurement manager agent.

Change Management & Adoption

In manufacturing, technology fails when it is thrown "over the wall" to the plant floor without context. Success with Gen AI is 20% technology and 80% culture.

The Evonence Approach to Adoption:

Stakeholder Alignment: We bring IT, OT (Operational Tech), and Business Unit leaders together early. Security needs to approve the data flow; Ops needs to validate the utility.

The "Human-in-the-Loop" Protocol: We design agents to be assistants, not replacements. For critical decisions (like shutting down a line), the AI provides the recommendation, but the human makes the call.

Pilot-to-Scale Framework: We don't boil the ocean. We start with one use case (e.g., the Maintenance Copilot on Line 4). We measure the time saved, refine the prompt engineering, and then scale to the rest of the facility.

Governance: We help you establish an AI Governance Council to review new agent requests, ensuring they comply with safety and compliance standards.

Why Evonence + Google Cloud?

Choosing the right partner is critical. You need a team that understands the nuances of Google Cloud and the realities of the manufacturing floor.

Evonence is a Premier Google Cloud Partner across the US and Canada with deep specialization in Gen AI, Data Analytics, and Work Transformation.

Our Value Proposition:

Unified Expertise: We don't just build AI models; we build the data estate that feeds them. We understand how to connect Gemini Enterprise with BigQuery and your existing Google Workspace environment for a seamless user experience.

Accelerated Time-to-Value: We have pre-built frameworks and reference architectures for manufacturing use cases. We can take you from "concept" to "proof of value" in weeks, not months.

Security-First Mindset: We understand that manufacturing IP is the lifeblood of your company. Our implementations prioritize data residency, compliance, and zero-trust security principles.

Full Lifecycle Partner: From the initial discovery workshop to the final deployment and ongoing managed services, we support your team every step of the way.

Conclusion & Next Steps

The manufacturing industry is at an inflection point. The leaders of the next decade will be those who successfully transition from being "data-rich but insight-poor" to being AI-enabled and operationally agile.

Gemini Enterprise provides the toolset to bridge the gap between your legacy systems and your future goals. But tools alone are not enough—you need a strategy.

Stop experimenting and start operationalizing.

Ready to transform your operations?

[Book a 60-Minute Innovation Workshop]

Discover how peer organizations in the US & Canada are using Gen AI to reduce downtime and optimize supply chains.